Waste Management

Management Approaches

| ◤ | In accordance with ISO 14001 certification, waste management regulations are established at each operation location |

| ◤ | All waste from TCC's plants is non-hazardous, and is treated in a non-harmful manner in accordance with regulations |

| ◤ | Investment in innovation or R&D to minimize waste |

Target

| ◤ | Achieve the "Zero Waste" goal of minimizing waste generation and maximizing resource recovery and reuse |

| ◤ | Cement plants set a goal in 2024 to achieve 100% conversion of waste into renewable resources, striving for "innocuous treatment and resource utilization" practices |

Treatment Process

| ◤ | General/Industrial waste: Recycled through the treatment with the high temperature in the rotary kiln process an reuse/Treated by certified vendors |

| ◤ | Valuable industrial wastes: Recovered by qualified third-party clearing agencies |

| ◤ | Investment in food waste treatment in Yingde Plant and Hoping Plant over 27.99 million from 2020 to 2023 |

Waste Disposal | Unit: metric tons

| 2020 | 2021 | 2022 | 2023 | |

|---|---|---|---|---|

| Hazardous waste | 0 | 0 | 0 | 0 |

| Non-Hazardous waste | 12,570.50 | 17,724.72 | 21,239.24 | 17,209.17 |

| Total waste recycled/reused | 3,338.61 | 3,881.23 | 9,673.86 | 7,811.95 |

| Total waste disposed | 9,231.89 | 13,843.49 | 11,565.38 | 9,397.22 |

| - Waste landfilled | 0 | 0 | 0 | 0 |

| - Waste incinerated with energy recovery | 0 | 0 | 0 | 0 |

| - Waste incinerated without energy recovery | 875.78 | 1,091.74 | 212.71 | 1,686.68 |

| - Waste sent to recycle/reuse | 8,356.11 | 12,751.75 | 11,352.67 | 7,710.54 |

Material Efficiency

| ◤ | Using high temperature, high retention time, high turbulence of the cement kiln used to process and treat industrial waste to achieve a circular economy |

|

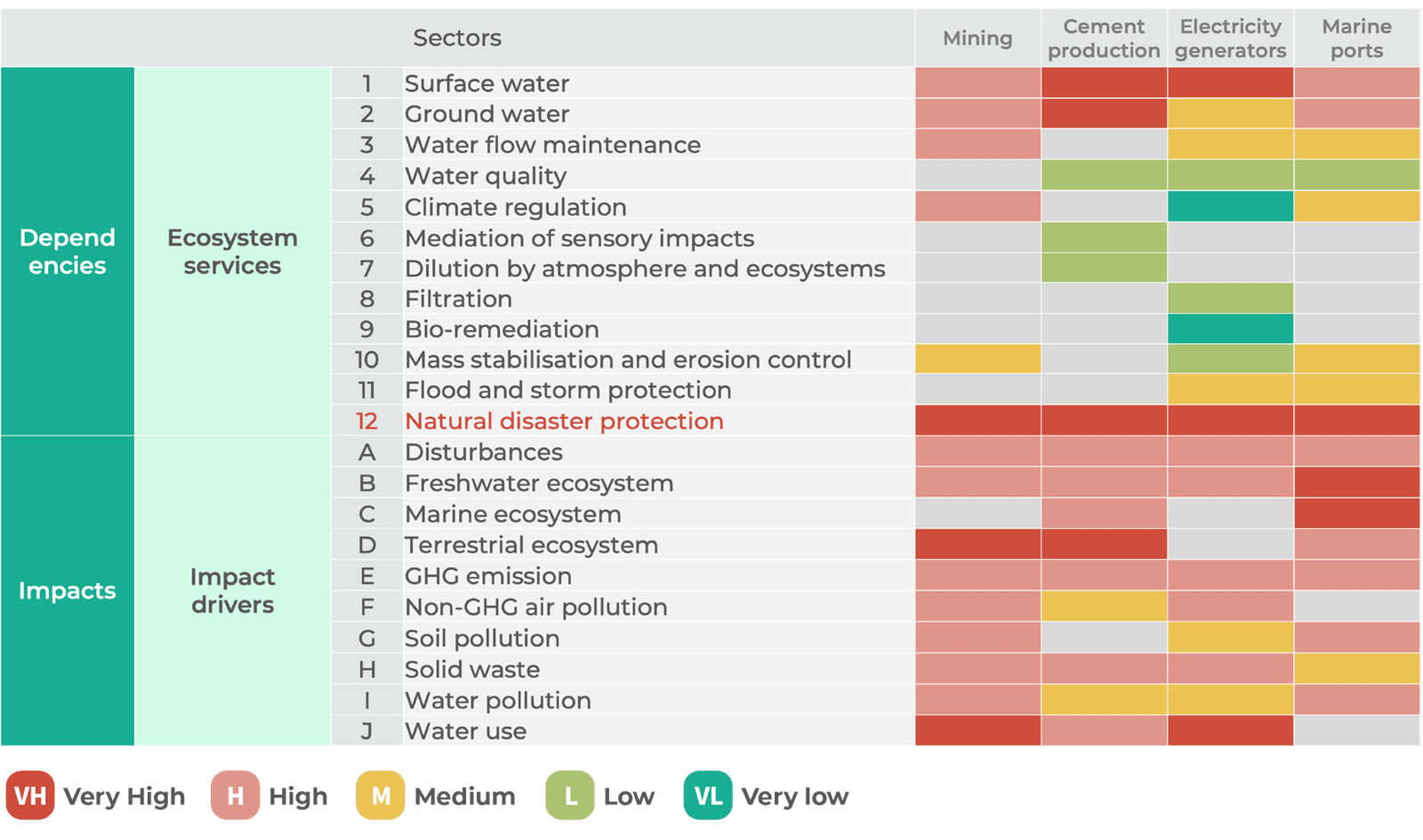

Share of Industrial Waste TCC Treated

|

TAIWAN

| Industry | 2022 Waste Treatment Volume (Metric Tons) | Share (%) | |

| Power | 665,630.27 | 57.60% | |

| Construction | 201,379.58 | 17.43% | |

| Steel | 151,345.57 | 13.10% | |

| Environmental Service | 94,083.66 | 8.14% | |

| Semiconductor | 18,268.94 | 1.58% | |

| Paper | 8,019.72 | 0.69% | |

| Chemical Textile | 5,279.67 | 0.46% | |

| Waste Incinerator | 5,210.67 | 0.45% | |

| Self-processed | 4,667.69 | 0.40% | |

| Metal Industry | 932.66 | 0.08% | |

| Water Treatment Plant | 643.28 | 0.06% | |

| Semiconductor Assembly | 222 | 0.02% | |

| Total | 1,155,683 | 100% | |

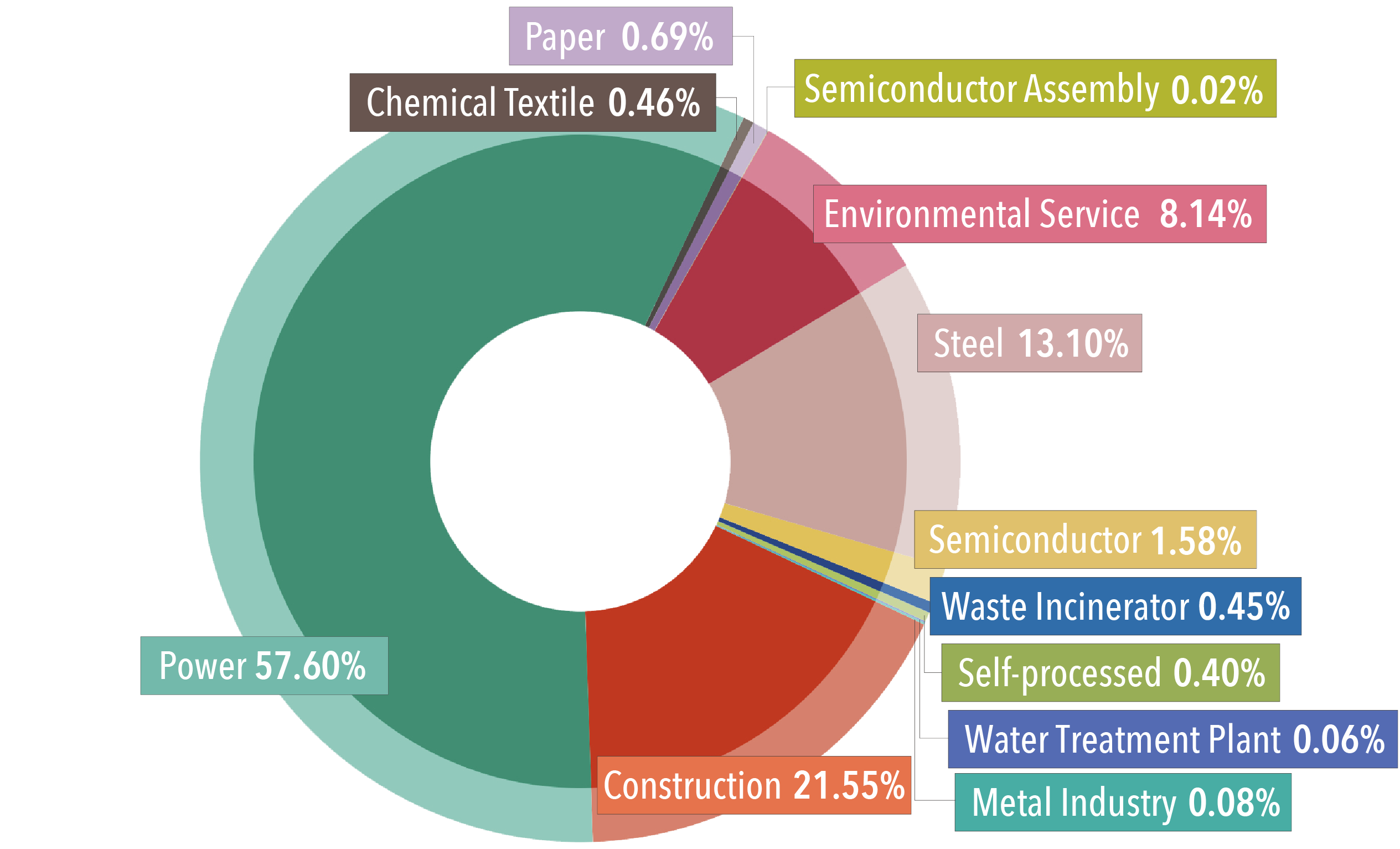

MAINLAND CHINA

| Industry | 2022 Waste Treatment Volume (Metric Tons) | Share (%) | |

| Power | 2,549,470 | 45.27% | |

| Steel | 694,716 | 12.34% | |

| Coal | 676,310 | 12.01% | |

| Mining | 73,128 | 1.30% | |

| Environmental Service | 500,478 | 8.89% | |

| Construction | 388,528 | 6.90% | |

| Chemical | 166,644 | 2.07% | |

| Metal Industry | 516,470 | 9.17% | |

| Paper | 83,520 | 1.48% | |

| Tire | 11,927 | 0.21% | |

| Semiconductor | 20,518 | 0.36% | |

| Total | 5,631,708 | 100% | |

Consumption of Raw Materials

TAIWAN

Unit: metric ton

| Non-recycled Raw Materials | Recycled Raw Materials | Total Amount of Raw Materials | Percentage of Recycled Raw Materials (Recycled Raw Materials / Total Amount of Raw Materials) |

|

|---|---|---|---|---|

| 2018 | 6,623,452 | 1,741,470 | 8,364,922 | 20.82% |

| 2019 | 6,783,203 | 1,973,542 | 8,756,745 | 22.54% |

| 2020 | 8,057,356 | 2,022,504 | 10,079,860 | 20.06% |

| 2021 | 7,493,992 | 2,138,492 | 9,632,484 | 22.20% |

| 2022 | 6,783,513 | 2,110,219 | 8,893,732 | 23.73% |

| 2023 | 5,862,906 | 1,523,551 | 7,386,457 | 20.6% |

MAINLAND CHINA

Unit: metric ton

| Non-recycled Raw Materials | Recycled Raw Materials | Total Amount of Raw Materials | Percentage of Recycled Raw Materials (Recycled Raw Materials / Total Amount of Raw Materials) |

|

|---|---|---|---|---|

| 2013 | 34,311,825 | 5,046,178 | 39,358,003 | 12.8% |

Water Management

|

Policy

TCC has established Water Management Commitment , committed to pursuing sustainable water resource utilization, enhancing water resource management, and improving water efficiency. Pledged to reduce water withdrawal and consumption, comply with relevant regulatory standards, rigorously monitor the quality of discharged water to prevent harm to ecosystems, water bodies, and human health due to wastewater, and ensure that employees and local residents have access to clean water

|

||||||||||||

|

Management Approaches

|

||||||||||||

|

Performance

|

||||||||||||

|

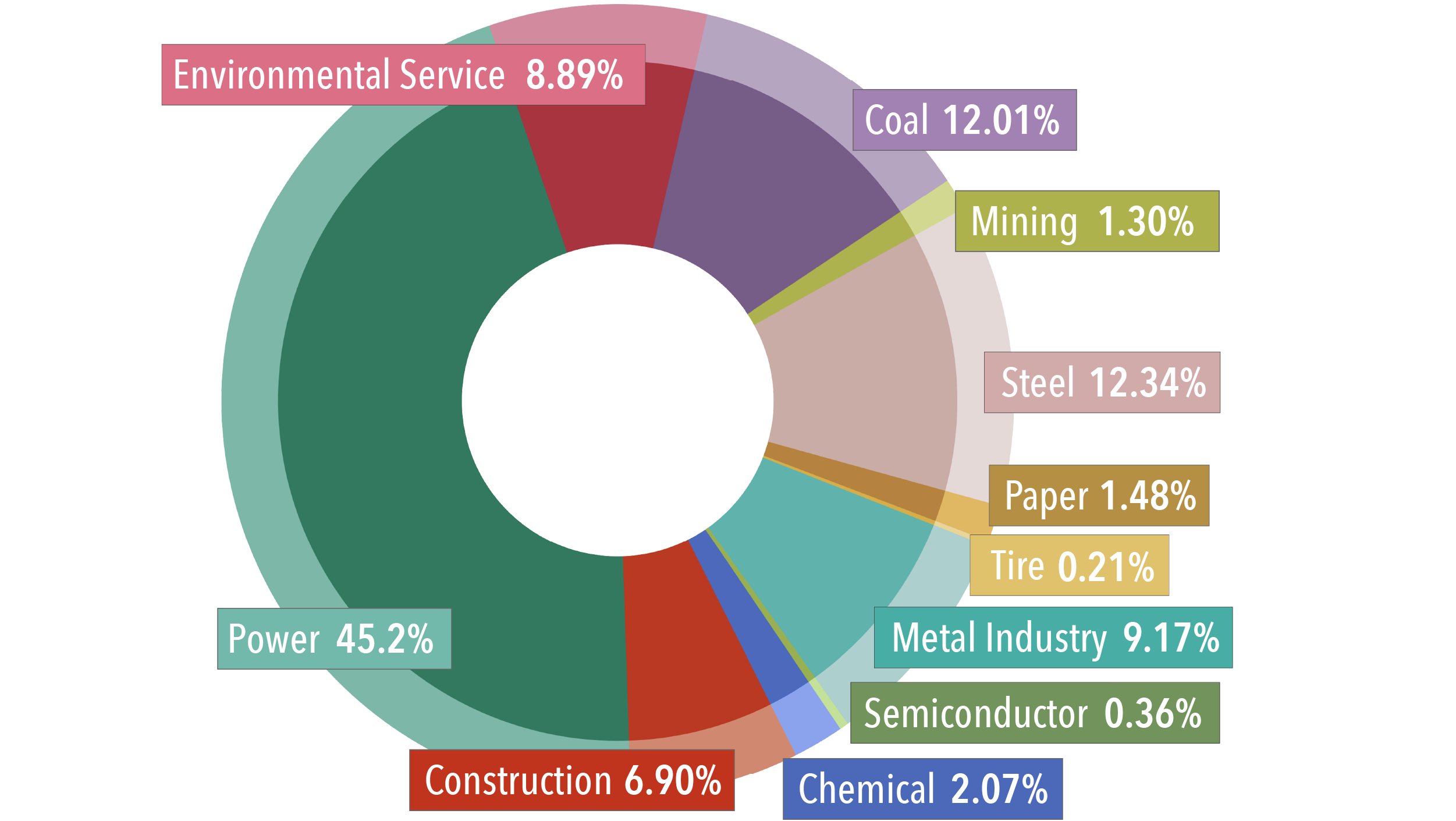

Targets

Unit: megaliter/metric ton of cementitious materials

|

Note: In 2023, due to the enhancement of dust suppression and control, the addition of desulfurization towers, and vegetation greening, the water withdrawal increased

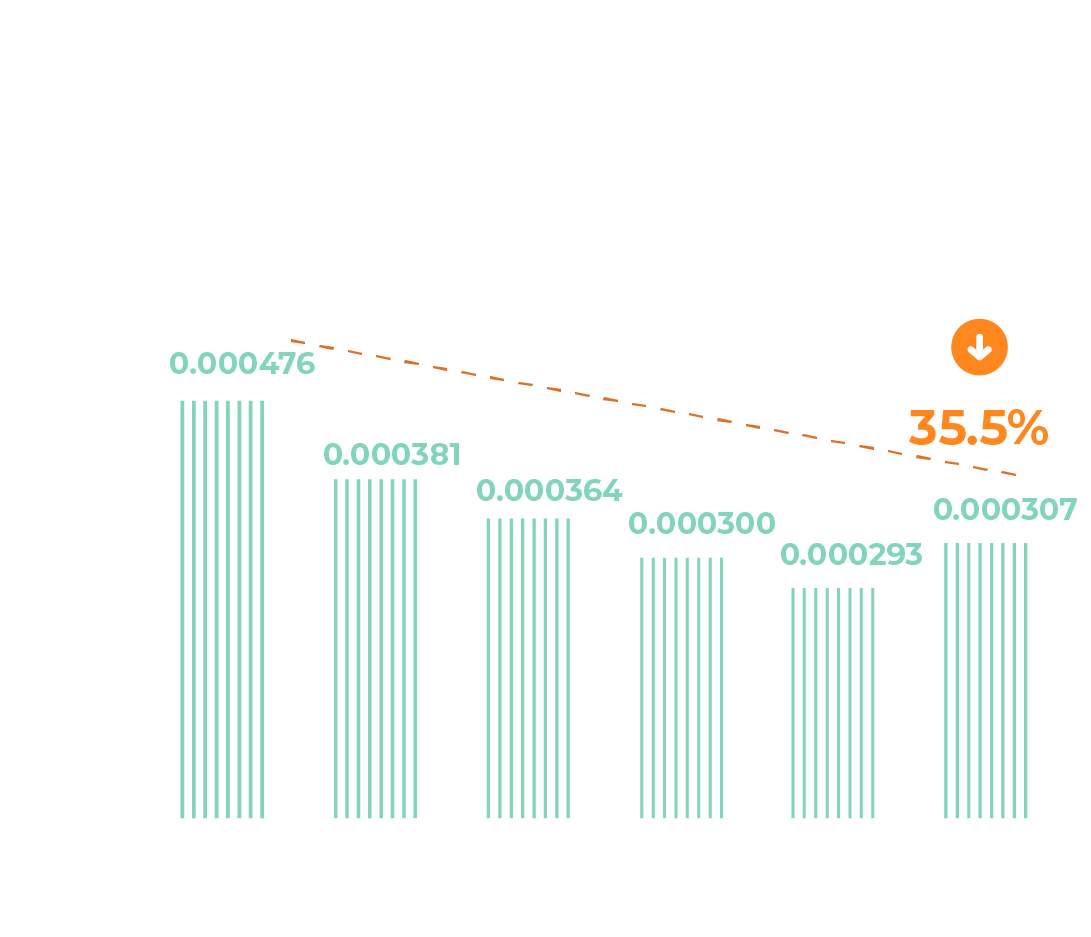

Biodiversity

|

Policy

|

||||||||||||||||

|

International Initiatives

|

||||||||||||||||

|

Reclamation of the Disturbed Lands

|

Biodiversity Risk Assessment

Scope

100% Cement Plants and Mines in Taiwan and Mainland China, Hoping Port, and Hoping Power Plant

| Operational Activities | Number of Sites and Area |

|---|---|

|

Overall: 61 sites|2,645.76 hectares

Of these, 24 sites for RMC Plants and Hong Kong Cement cover a total area of 26.05 hectares. These sites are not located near any natural areas. TCC will evaluate the initiation of biodiversity assessment procedures.

|

|

|

Assessment: 14 sites|2,619.71 hectares

|

|

| Own operations* |

Cement Plant in Taiwan: 2 sites|68.32 hectares

Cement Plant in Mainland China: 12 sites|741.54 hectares

|

| Upstream activities |

Mines in Taiwan: 2 sites|300.7 hectares

Mines in Mainland China: 19 sites|1,323.35 hectares

Hoping EcoPort: 1 sites|158.8 hectares

|

| Downstream activities | |

| Adjacent areas to own operations | Hoping Power Plant: 1 sites|27 hectares |

|

Exposure: 2 sites|300.70 hectares

|

|

|

Management Plans: 2 sites|300.70 hectares

|

|

|

Methodology

|

||||

|

Results

|

SBTN-AR3T

| Avoid | Reduce | Regenerate/Restore | Transform |

|---|---|---|---|

| 100% TCC-owned quarries have passed environmental impact assessment. TCC formulates Biodiversity policy and avoids mining in protected areas | Implement Membrane Bioreactors to reduce wastewater pollution, please refer to TCC Sustainability Report CH2.2 Water Resources Management | Prioritize native plants and select species fit for the area to restore the mine, including Hoping Mine Restoration Project and Taibaishan Mine Ecological Restoration Project, please refer to TCC Sustainability Report CH4.2 Forest Restoration | Transform the terminated mine into a hiking trail and flood detention park, connecting urban blue-green spaces and providing flood control service, please refer to TCC Sustainability Report CH4.2 Forest Restoration |

| Set up slope protection mesh to mitigate soil erosion | |||

| Remove invasive species, White Popinac, to reduce the ecological threat, please refer to TCC Sustainability Report CH4.4 Nature-based Solutions | Install nesting boxes to provide habitats for bird reproduction in mining area | Shift to a circular economy, reusing waste as a resources to replace the raw materials/fuels for cement, reducing waste and GHG emissions, please refer to TCC Sustainability Report CH2.3 Resource Recycling | |

| Cement plants boost reclaimed water use, enhance water efficiency and avoid freshwater withdraw, please refer to TCC Sustainability Report CH2.2 Water Resources Management | Plant streetlights automatically adjust to sunrise times to minimize light pollution | ||

| Silencers are installed on plant equipment to lower noise | Applying natural organic compost to enhance soil’s physical and chemical qualities | Engage with tribes and local communities, offering economic opportunities, scholarships, emergency funds, and educational support, please refer to TCC Sustainability Report CH5.6 Social Inclusion | |

| Implement vertical shaft system to convey limestone, reducing the GHG emissions, noise, and dust from transportation, please refer to TCC Sustainability Report CH2.2 Air Emissions Management |

|

Targets

|

||||||||||||

|

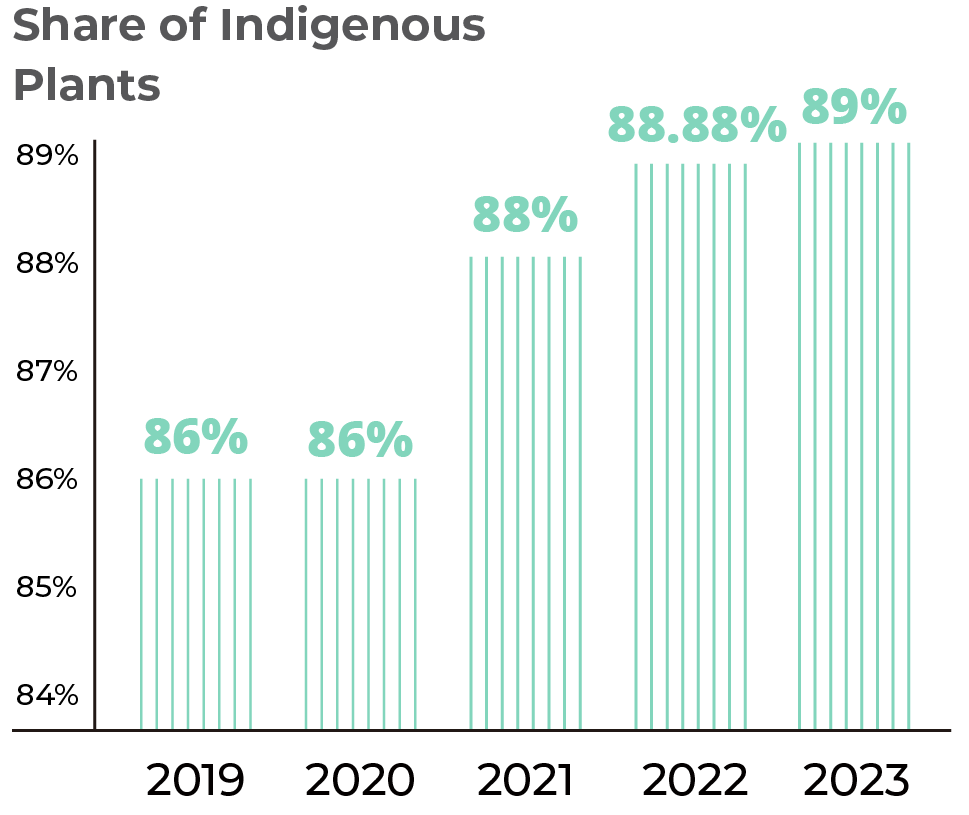

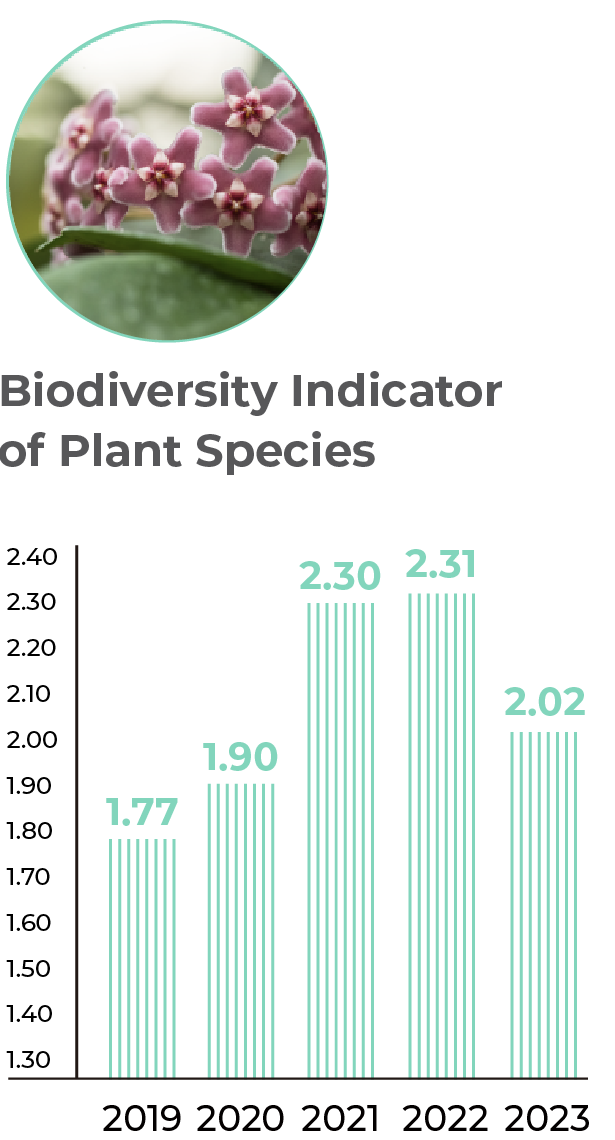

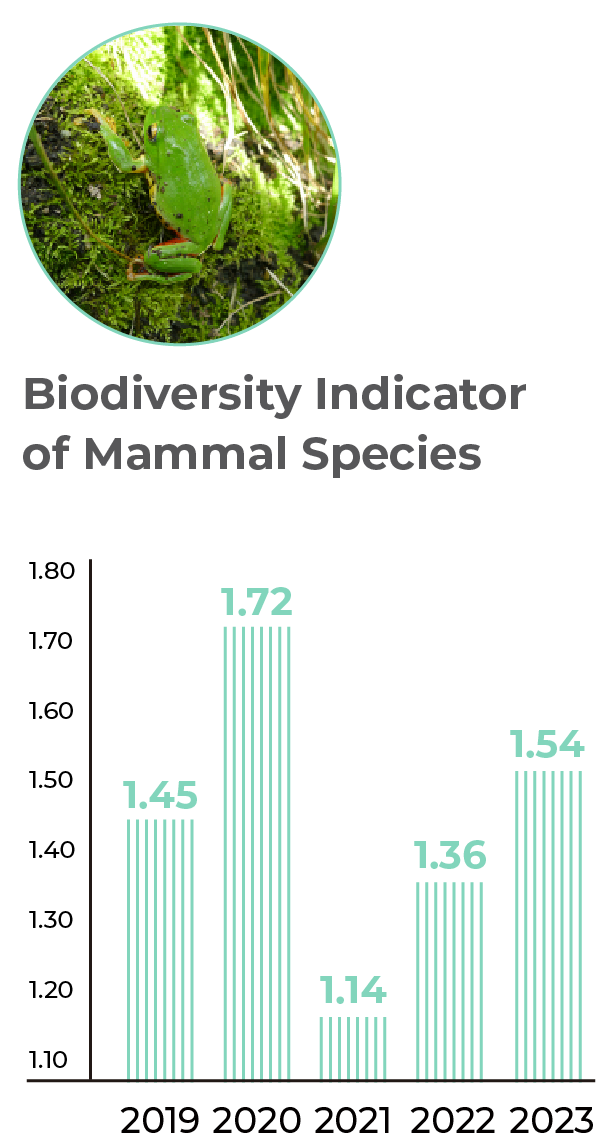

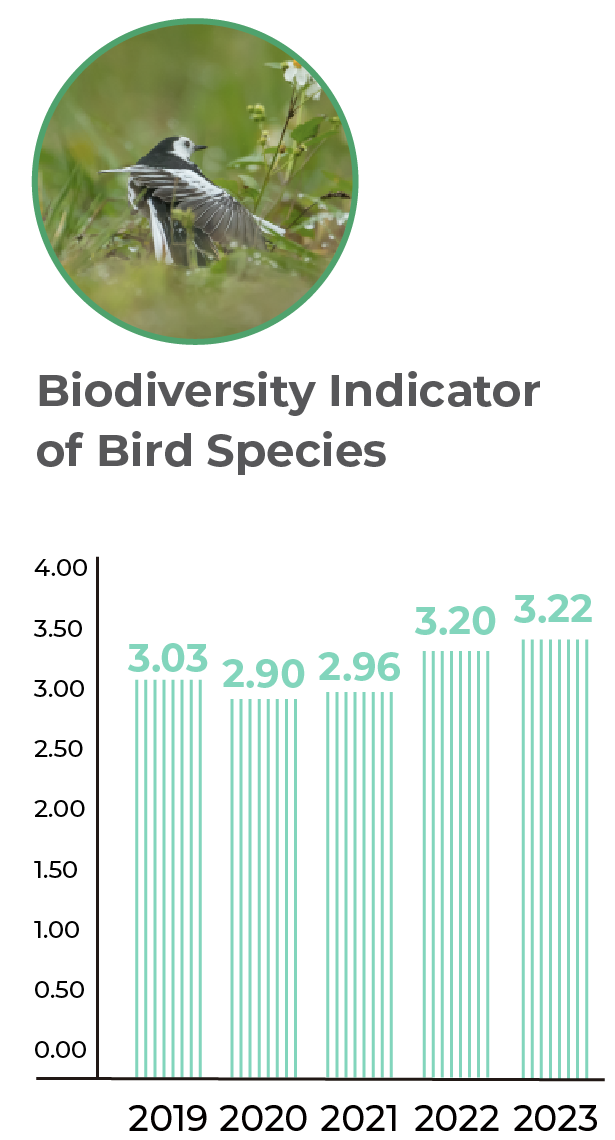

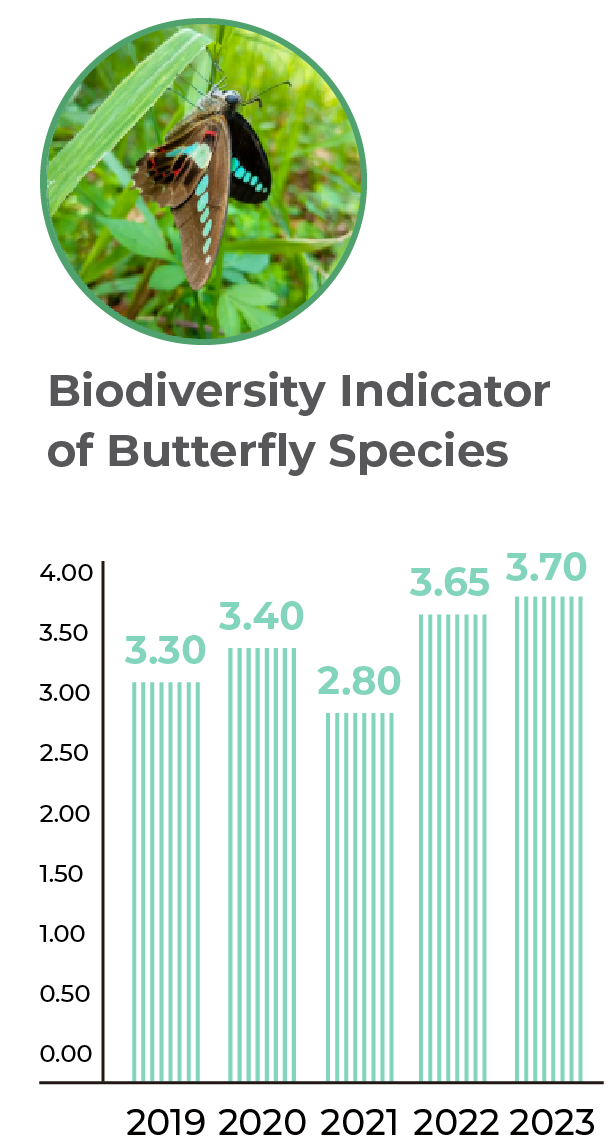

Performance

|

||||||||||||

|

Note:1).All operating sites od TCC Group are not located in ecological conservation or rehabilitation area. 2).Biodiversity indicators exhibit seasonal variations of different species.

Hoping Mine Environmental Monitoring Report (CH)

Suao Mine Environmental Monitoring Report (CH)

Mine Ecosystem Services Assessment Report (CH)