Alternative Clinker & Clinker-to-Cement Ratio

Management Approaches

| ◤ | According to the International Energy Agency (IEA) recommendations, a key area for carbon reduction in the cement industry is to lower the clinker-to-cement ratio |

| ◤ | In addition to investing in alternative raw materials or limestone for clinker production, efforts are continuously made to search for and test new materials as substitutes for clinker |

| ◤ | In Taiwan, it is required to comply with CNS 61 regulations, where the addition ratio of cementitious materials in cement must be less than 10% |

| ◤ | The Cape Verde plant utilizes natural volcanic ash as a substitute for clinker, with 0 kg of carbon emissions per ton of volcanic ash, directly replacing traditional clinker which has a carbon emission of 750-800 kg per ton |

| ◤ | The Ghana plant utilizes the chemical properties of kaolin to reduce the use of thermal energy and improve energy efficiency |

Clinker-to-Cement Ratio

Target | Taiwan & Mainland China (weighted average)

| ◤ | 2025: 0.796 |

| ◤ | 2030: 0.780 |

| ◤ | 2050: 0.570 |

Performance | Taiwan & Mainland China (weighted average)

| 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|

| 0.826 | 0.823 | 0.816 | 0.799 |

Alternative Materials and Fuels for Cement ProductionThe Best Way to Effectively Reduce Carbon Emissions

Alternative Raw Material

Management Approaches

| ◤ | Actively engaged in the development of alternative materials, utilizing recycled resources as alternative raw material |

| ◤ | Continuously develop alternative raw material sources such as calcium silicate boards and construction waste |

Target | Taiwan & Mainland China (weighted average)

| ◤ | 2025: 21% |

| ◤ | 2030: 22% |

| ◤ | 2050: 25% |

Performance | Taiwan & Mainland China (weighted average)

| 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|

| 16.4% | 18.2% | 19.6% | 18.7% |

*% alternative raw materials contained in concrete: 43.25% in 2023

*TCC has no other building materials such as asphalt (excluding natural raw materials e.g. gypsum, pozzolan)

Alternative Fuel

Management Approaches

| ◤ | Actively utilizing diverse alternative fuels, and continue to develop categories such as waste wood, waste plastics, waste textiles, and non-hazardous oil sludge in 2023 |

| ◤ | In 2023, TCC and ITRI jointly completed the construction of the “SRF with high heating value co-firing and clean integration system for cement kiln”, collaborating in developing high calorific value SRF materials and co-firing technology |

| ◤ | Due to regulatory restrictions in Taiwan, it is difficult to effectively increase the TSR of alternative fuels. TCC is actively discussing with the authorities about the possibility of adjusting the chloride ion limit (240ppm) |

Target of Thermal Substitution Rate of Alternative Fuels|Taiwan & Mainland China (weighted average)

| ◤ | 2025: 25% |

| ◤ | 2030: 35% |

| ◤ | 2050: 50% |

Oversea Cement Business

| ◤ | OYAK Aslan Plant | 2030: 70% |

| ◤ | OYAK Ankara Plant | 2030: 65% |

| ◤ | CIMPOR Alhandra Plant | 2025: 80% |

| ◤ | CIMPOR Souselas Plant | 2024: 65% |

Performance

Thermal Substitution Rate of Alternative Fuels (%) | Taiwan & Mainland China (weighted average)

| 2021 | 2022 | 2023 |

|---|---|---|

| 1.2% | 7.65% | 12.6% |

| ◤ | Leveraging local advantages, the residual materials from the harvest of specialty crops will be tested as alternative fuels |

| ◤ | By utilizing cement kiln co-processing technology, the removed alien species White Popinac is converted into biofuels, not only achieving resource recycling but also helping to maintain urban natural ecology |

Energy Efficiency

|

Management Approaches

100% plants in Taiwan and Mainland China obtained ISO 50001 certification

|

|

Target

Improve energy productivity by 50% by 2040 relative to 2016 baseline year

Continuously strengthen power generation by waste heat recovery and energy-saving technological improvements

|

|

Performance

TCC energy efficiency exceeding the target, selected in EP100 ”2023 Annual Report”

|

Energy Consumption

| 2020 | 2021 | 2022 | 2023 | |

|---|---|---|---|---|

| Total non-renewable energy consumption (Unit: GJ) | 157,944,110.00 | 135,370,307.00 | 109,735,578.00 | 94,141,360.00 |

| Total renewable energy consumption - alternative fuels & renewable energy (Unit: GJ) | 19,047.00 | 466,949.00 | 1,743,904.00 | 2,069,322.00 |

| Total non-renewable energy consumption (Unit: MWh) | 47,873,363.89 | 37,602,863.06 | 30,482,105.00 | 26,150,377.78 |

| Total renewable energy consumption - alternative fuels & renewable energy (Unit: MWh) | 5,290.83 | 129,708.06 | 484,417.78 | 574,811.67 |

Note: 1 GJ = 0.27777778 MWh. Due to updates in activity data in October, 2024, recalculations were performed.

Power Generation by Waste Heat Recovery

TAIWAN & MAINLAND CHINA

Note: Due to the staggered production plan from 2022 to 2023, the power generation by waste heat recovery decreased

Methane

The National Oceanic and Atmospheric Administration (NOAA) reported in 2021 that the increase in atmospheric methane levels reached the largest magnitude measured in 40 years. The COP26 began to focus on the issue of methane, and more than 150 countries have now signed the Global Methane Pledge (GMP). Methane has a global warming potential 27.9 times that of carbon dioxide, making it a significant contributor to climate change, especially since landfill waste is one of the main sources of methane emissions. Utilizing the high temperatures at the core of the cement industry, TCC provides co-processing services for domestic waste in cement kilns, avoiding the methane issues caused by waste accumulation and committing to reducing the impact of methane.

| Unit: metric ton | Amount of Co-processed Domestic Waste | Avoided Methane Emissions |

|---|---|---|

| Hoping Plant | 13,762 | 810.97 |

| Shaoguan Plant | 17,672 | 796.36 |

| Anshun Plant | 5,204 | 234.49 |

| Jingzhou Plant | 34,744 | 1,565.63 |

| Total | 71,382 | 3,407.45 |

|

TAIWAN

|

|

MAINLAND CHINA

|

| Note 1: | The calculation of methane emissions from solid waste landfilling is based on the formula provided in the 2024 Republic of China National Greenhouse Gas Inventory Report, assuming the landfilling method is a properly managed landfill |

| Note: 2 | The composition of Hualien's garbage is derived from the 2023 Environmental Protection Department's analysis of the nature of garbage in various counties and cities (wet basis), with paper at 48.13%, textile at 3.76%, wood/bamboo/straw/leaves at 3.60%, kitchen waste at 12.60%, and plastics at 30.50% |

Low-Carbon Construction Materials

| ◤ | Carbon reduced by 15.4% compared to Portland Type I (base year: 2016) |

| ◤ | Lower carbon, stronger early strength for general construction and engineering |

| ◤ | Expected to 100% replace the traditional Portland Type I by 2026 |

| ◤ | Production in line with CNS 15286 |

MOE Gold-rated Green Mark

MOE Carbon Footprint Label

MOE Carbon Footprint Reduction Label

ISO14067 Carbon Footprint of Products

MOI Green Building Material Label (to be issued in Q3 2024)

BSMI CNS Mark

| ◤ | Consistent slump, superior workability |

| ◤ | Stronger early strength |

| ◤ | More actionable, lower carbon emissions |

| ◤ | High durability |

| ◤ | For general construction and engineering |

MOE Carbon Footprint Reduction Label

Taiwan Architecture & Building Center Recycling Green Building Material Label

ISO14067 Carbon Footprint of Products

Good Ready-Mixed Concrete (GRMC)

MOI Green Building Material Label (to be issued in Q3 2024)

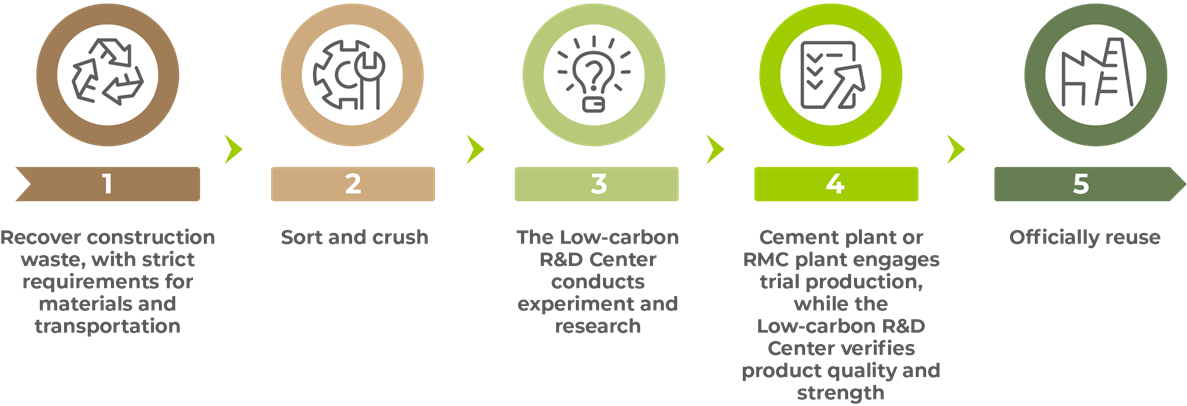

Construction Waste Solutions

In 2023, TCC invested in the recycling and treatment of construction waste, planning to reuse it as alternative raw materials or fuels for cement or concrete, and continued to develop sources of alternative materials such as calcium silicate boards and construction waste.

| ◤ | Construction waste can be used as filler for graded aggregate, fine aggregate or admixture for concrete, and alternative clay for cement |

| ◤ | The remainders are sorted as alternative fuels for the cement plant |

Construction Waste Recycling Material

Construction Waste Recycling Material

| ◤ | Alternative Raw Material: 70% |

| ◤ | Alternative Fuel: 20% |

| ◤ | Scrap Metal: 2-3% |