2050 Net-zero Pathway for the Cement and Concrete Business Units Worldwide

TCC's Road Map to 2050 Net-zero Pathway for the Cement and Concrete Business Units Worldwide

Coverage

The net-zero pathway scope covers all operational sites in Taiwan, Mainland China, CIMPOR, and OYAK CEMENT

Methodology

.png)

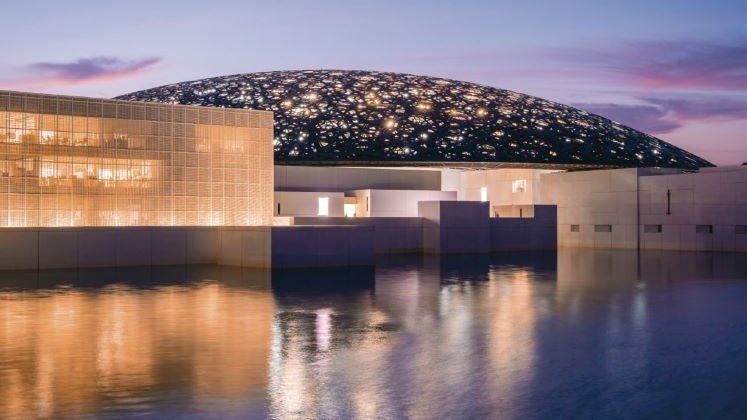

Avoided Emissions of TCC Business Units Worldwide

Using global standards and international methodologies, the external carbon reduction capabilities of low-carbon construction materials, renewable energy, energy storage, and the battery industry are assessed, aiming to transform and enhance corporate value through increased influence.

Methodology

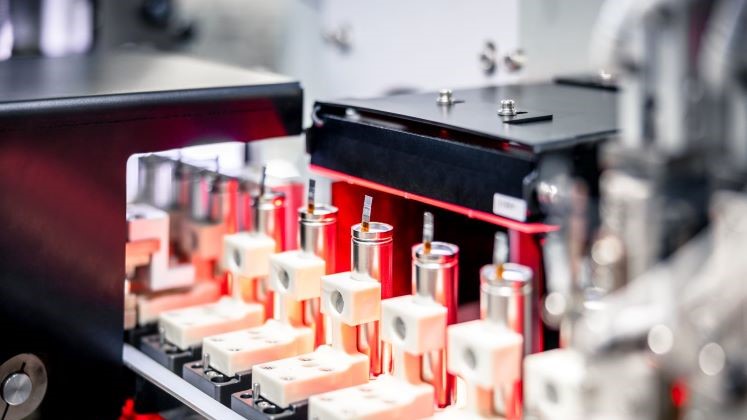

Low-carbon Construction Materials | Resource Recycling | Green EnergyRenewable Energy | Green EnergyEnergy Storage | Green EnergyBattery |

2024 Performance -962,000 2030 Target -1.69million |  2024 Performance -92,000 2030 Target NA |  2024 Performance -65,000 2030 Target -530,000 |  2024 Performance -149,000 2030 Target -160,000 |  2024 Performance -3,399 2030 Target -320,000 |

Unit: metric ton CO 2e