Initiating new generation pure oxygen carbon capture technology in the era of carbon innovation

- Home

- Sustainable E-newsletter

- Initiating new generation pure oxygen carbon capture technology in the era of carbon innovation

Environmental 2024 Vol.01

Initiating new generation pure oxygen carbon capture technology in the era of carbon innovation

- #Carbon Capture

-

Share

In 1824, Portland cement was invented.

In 2024, the 200th year since the invention of cement. At the same year, Taiwan Cement Corporation (TCC), in collaboration with tkPOL from Germany, is initiating a new generation of pure oxygen carbon capture technology in the era of carbon innovation, giving the cement process a new life of "net zero" emissions.

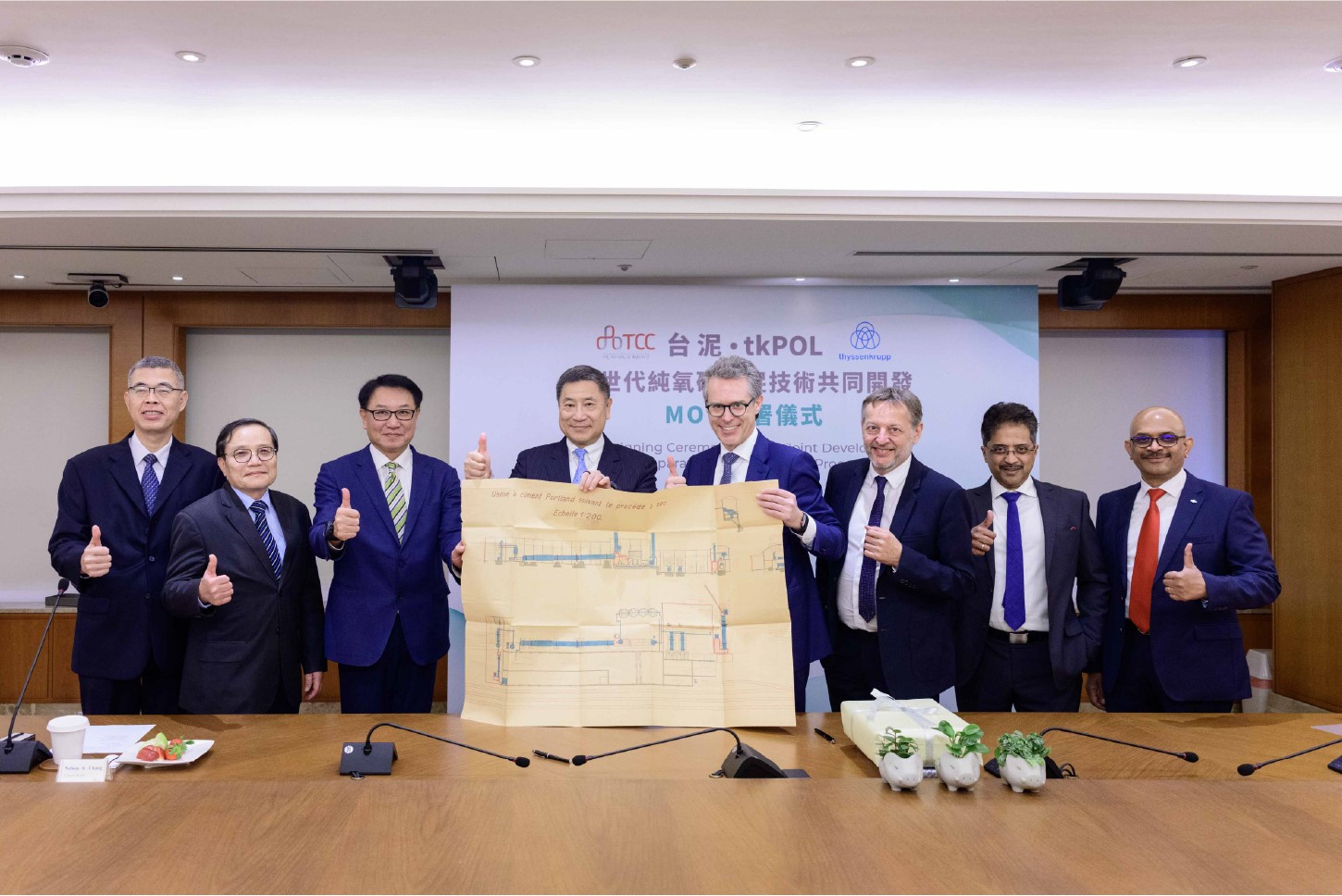

"Without cement, discussions about civilization and energy transformation are empty talk. However, cement also emits greenhouse gases. This collaboration aims to solve this problem. Polysius is a gold standard in the cement industry, and it is an honor to create the future together with you, not only for the cement industry but also for the whole world." At the beginning of 2024, Chairman Nelson Chang of TCC welcomed the team from thyssenkrupp Polysius (tkPOL), a subsidiary of the well-known German heavy industrial group ThyssenKrupp Industrial Solutions, at the Taipei headquarters, signing a memorandum of understanding (MOU) for carbon capture project cooperation. tkPOL is currently assisting cement companies in Europe, such as HeidelbergCement, in the Catch4Climate forward-looking project. It is one of the world's important carbon capture technology teams. The cooperation between TCC and tkPOL becomes Asia's first carbon capture project exclusively designed for cement calcination process.

This project uses the No. 1 kiln at the TCC Hualien Hoping Plant as the carbon capture technology site. Hoping Plant will host the concept, with a Separate Oxyfuel Calciner technology adding pure oxygen to the calcination process, increasing the concentration of carbon dioxide captured to more than 90%, while reducing the energy required. The next step is using pure oxyfuel technology to increase the concentration of carbon dioxide produced during clinker calcination. And then to be purified and reused or liquefaction storage to production and achieve carbon reduction effects. It is expected to be completed in 2026, with the goal of mastering the core technology for commercialization by 2030, capturing 100,000 tons of carbon dioxide annually.

Carbon capture is seen as a key technology for global climate reversal. TCC continues to invest in forward-looking projects, while evaluating the subsequent applications of carbon dioxide capture. It provides cross-industry services for industrial welding, chemical industry, food processing, etc., and evaluates the feasibility of storage and carbon credits in accordance with government policies, continuously seeking a balance between human civilization development and nature.

You may also like

TCC GROUP HOLDINGS

SUSTAINABLE E-NEWSLETTER.