TCC Implements AI Monitoring to Enhance Operational Efficiency and Reduce Energy Waste

- Home

- Sustainable E-newsletter

- TCC Implements AI Monitoring to Enhance Operational Efficiency and Reduce Energy Waste

Environmental 2025 Vol.01

TCC Implements AI Monitoring to Enhance Operational Efficiency and Reduce Energy Waste

- #AI Monitoring

-

Share

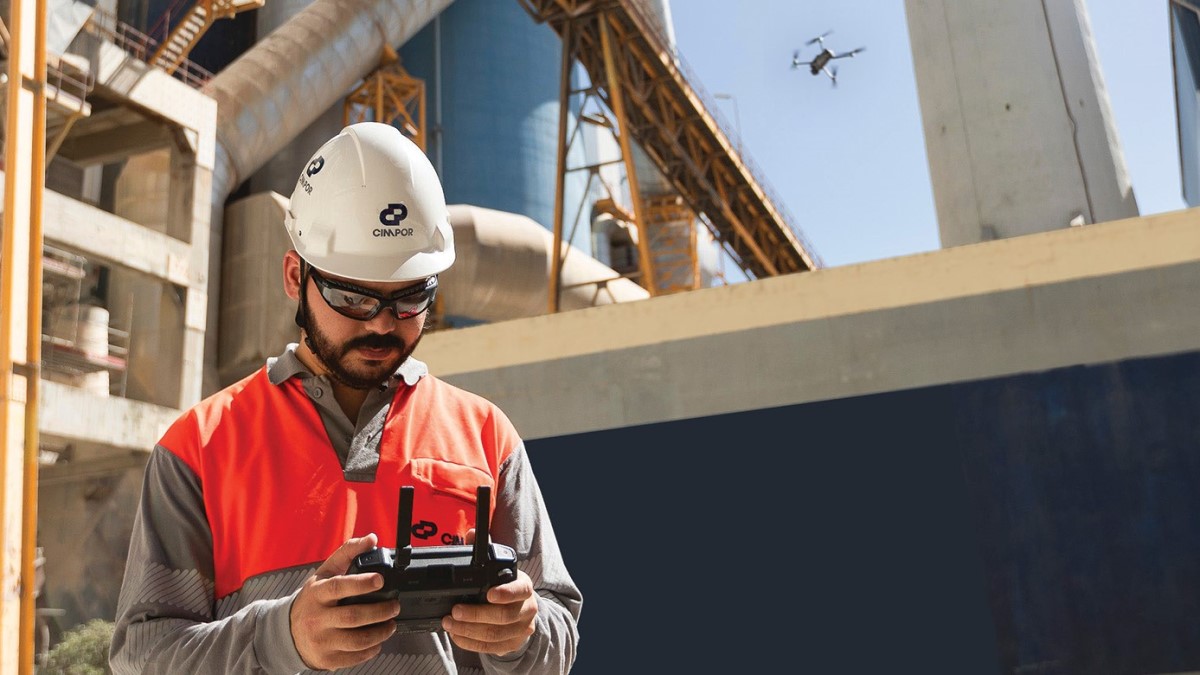

TCC's subsidiary CIMPOR uses of drones for quick and accurate inspections, reducing the time and costs associated with these operations

Comprehensive AI Monitoring for Enhanced Efficiency and Sustainability

In March of this year, TCC Group announced its subsidiary, CIMPOR, in collaboration with UK-based tech startup FIZIX, has initiated one of the most comprehensive machinery health monitoring programs in the global heavy industry sector, centered on the Internet of Things (IoT) and Artificial Intelligence (AI).

Utilizing smart sensors provided by FIZIX and AI-driven equipment health monitoring, this initiative aims to significantly boost the operational efficiency and sustainability standards of cement plants. Starting with 25 cement production sites across six countries, including Turkey, Portugal, Africa, and Europe, the project will deploy 10,500 smart sensors for real-time monitoring and AI data analysis.

By 2026, the program will further expand to cement plants in Taiwan and mainland China, covering TCC's global cement operations.

Unlike traditional cement production, where equipment maintenance relies on periodic inspections or post-failure repairs, this project uses smart sensors to gather real-time equipment data. Through AI-driven real-time analysis of operational status, anomalies are identified and predicted in advance.

Moreover, machine learning and big data analytics developed by FIZIX enable predictive maintenance, reducing the occurrence of unexpected failures. Additionally, the project's cloud-based system ensures real-time data synchronization and allows professional teams to provide remote support and predictive analysis, optimizing production processes and enhancing operational flexibility.

In the future, the integration of AI will further reduce energy waste and carbon emissions, making cement production more environmentally friendly and economically efficient.

Diversified AI Applications Across Cement and Energy Sectors

CIMPOR uses of AR glasses for predictive maintenance, analyzing and solving problems remotely

TCC has prior experience in AI implementation, such as deploying drones, smart glasses, and AI image analysis in European cement plants for intelligent site inspections and environmental monitoring, providing early warnings for occupational safety risks and environmental anomalies.

In ready-mix plants, AI models are used to accurately analyze production data, predict concrete strength and slump, and offer optimal mix ratio recommendations, accelerating the development of low-carbon mixes and recycled building materials.

Looking Ahead: DIN Program to Attract AI Talent

In alignment with Chairman Nelson Chang's vision for TCC, "Mobilis in Mobili (Changing in a changing world)," TCC has launched the "Digital Intelligence Navigator (DIN) Program" this year to attract top talent in the digital and AI fields. This team will participate in smart grid projects, carbon emissions management, AI-driven supply chain optimization, energy forecasting, and smart energy storage, driving TCC's cross-industry and cross-border digital and low-carbon transformation. The DIN team is not only a strategic force but also a key driver in deeply integrating technology, industry, and sustainable development.

"We must move dynamically in the wave of change, shaping the future before it shapes us." TCC will continue to invest in AI technology and innovation, enhancing its competitiveness and aiming to set industry benchmarks in the cement and energy sectors, contributing to industrial intelligence and sustainable development.

You may also like

TCC GROUP HOLDINGS

SUSTAINABLE E-NEWSLETTER.