Occupational Safety & Health

TCC is dedicated to creating a safe and healthy work environment with the "human-centric" approach

TCC Group Holdings commitments Total Care Commitment, endeavoring to construct a healthy and safe workplace. TCC has established "Occupational Safety and Health Commi ee" and holds quarterly meetings to discuss employee safety and health issues. In addition to regularly monitoring the workplace environment, the company annually passes external third-party audits for its ISO 45001 Occupational Health and Safety Management System and ISO 14001 Environmental Management System to ensure a safe and healthy work environment.

The certificate for the Operational Headquarters is valid until December 22, 2026. For the Cement Plants, the certificates are valid until September 22, 2026 (Hoping Plant) and August 15, 2028 (Suao Plant). The Product Plant certificate is valid until May 19, 2027.

In terms of internal safety management, the Occupational Safety and Health Management Office regularly conducts on-site inspections to comprehensively evaluate the performance of each plant's occupational safety and health measures. To enhance overall safety awareness, internal auditors from each department receive qualification training in accordance with ISO 45001 and ISO 14001 regulations.

To strengthen risk control, TCC introduces AI technology starting in 2025, installing smart cameras in high-risk areas at each plant. It will also implement an occupational disaster and major incident reporting system to provide a convenient channel for reporting abnormal events and a robust mechanism for investigating and analyzing occupational incidents, thereby continuously improving the safety and health management system.

Policy

Committed to a safe workplace and zero occupational injuries, TCC's "Internal Control Policies for Occupational Safety and Health Management" apply to all Group employees, outsourced workers, and contractors. The safety regulations include "Occupational Safety and Health Policy Statement," "Occupational Safety and Health Management Regulations," "Occupational Safety and Health Management Plan," and "Occupational Safety and Health Code of Practice," promoting a safety culture through behavior-based management. CIMPOR and OYAK CEMENT also prioritize employee OHS in their Integrated Management System Policy.

Coverage

100% employees

Supplier

contractors

Occupational Safety and Health Committee

Monthly TCC meetings, chaired by the Chairman, begin with OHS performance and improvement plans.

TCC's OHS management system includes legally required Labor Safety and Health O ces (LSH O ces) at each site. Taiwan sites hold quarterly OHS meetings, while Mainland China plants meet monthly; led by the Chief Commissioner, these meetings track progress, review improvements, decide OHS ma ers, and report to headquarters.

In 2025, "Safety Improvement Promotion Teams" were formed at each plant to boost OHS performance and prevent accidents.

Monthly "Group OHS Meetings" are held, with headquarters Occupational Safety and Health Management O ce overseeing plant improvements and implementation. Safety awareness is also reinforced via presidential-approved disciplinary actions.

For CIMPOR and OYAK CEMENT, the CIMPOR Group's Board of Directors supervises their OHS Commi ee's operations. A digital OHS monitoring platform consolidates accident reports and data, enabling the commi ee to continuously identify, manage risk events, and analyze trends.

Performance Bonus Assessment

To drive management intensity, TCC, CIMPOR and OYAK CEMENT have clear remuneration linkage mechanisms: TCC's management team's annual performance bonuses are adjusted based on OHS performance; 10% of CIMPOR employees' variable pay is directly linked to OHS performance; OYAK CEMENT's OHS incentive program rewards employees for promoting safety awareness among partners and visitors.

- Rewards and disciplinary mechanisms for occupational safety and health evaluations at each plant.

TCC's Safety Inspection Mechanism

Type | Description | Frequency |

|---|---|---|

Internal Inspection | The Occupational Safety and Health Management Office audits the cement plants | 1 time/ week |

| The Occupational Safety and Health Management Office audits the ready-mix plants and subsidiary factories | 1 time/ week | |

| Plant managers and occupational safety and health management supervisors audit | 2 times/ week | |

| HQ Managers or above the manager level | Irregularly | |

External Audit | ISO 45001、TOSHMS、Validation and Audit | 1 time/ year |

| ISO 14000 Validation and Audit |

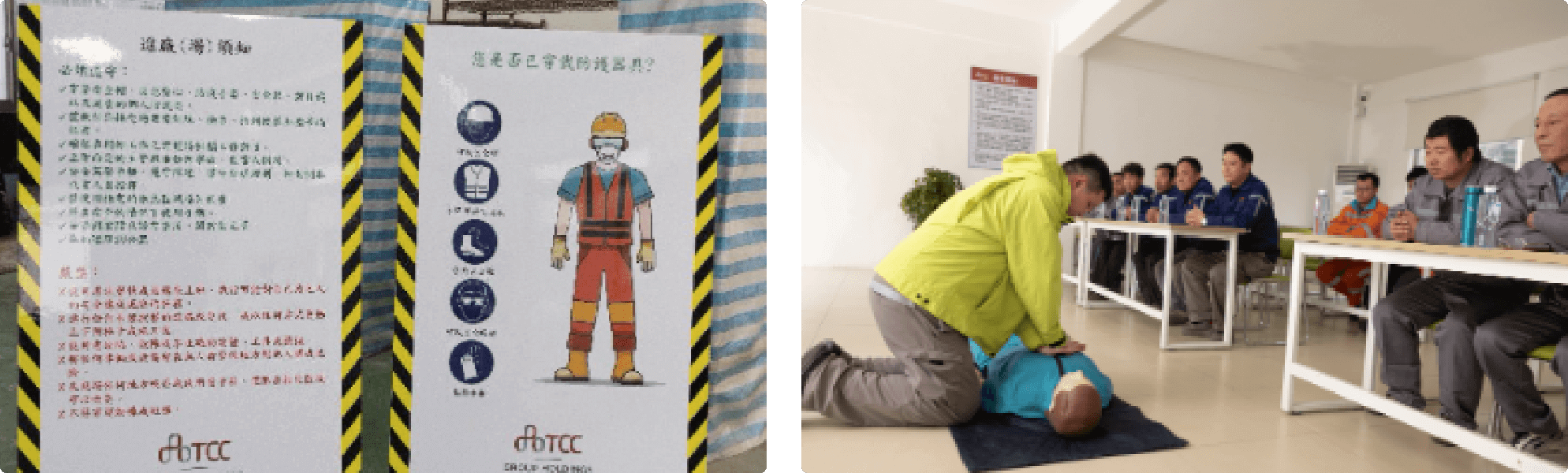

Health & Safety Education Training

TCC conducts annual labor, occupational safety, and disaster prevention training per government regulations. Employees regularly undergo new and refresher training for certifications in first aid, oxygen-deficient operations, hazardous equipment, and OHS supervision. The Company also actively participates in government-organized disaster prevention seminars and certification training.

Taiwan, Mainland China, CIMPOR, and OYAK CEMENT

Accumulated Employee Training A endance

118,358participants

Accumulated Training Hours

62,482hours

Taiwan | Mainland China | CIMPOR | OYAK CEMENT |

|---|---|---|---|

Annual Training Hours

Topics include

| Annual Training Hours

Annual "Safety Re-education" Training

| Annual Training Hours

Topics include

| Annual Training Hours

Strengthening Occupational Safety Culture Training

|

Seven Major Life Safety Rules

Isolate and Lockout All Power Sources

- Staff have helped me identify all power sources.

- I have ensured all power sources are isolated, locked out, or tagged.

- Before touching any equipment, I have made sure to wear insulated protective gear.

Confirm You Are Authorized and Have Followed Confined Space Work Requirements

- I have obtained permission to enter the confined space.

- I have the proper qualifications to work in a confined space.

- Staff have helped me confirm that all electrical hazards have been isolated, and the space has sufficient oxygen and no dangerous gases.

- I have confirmed that a qualified standby worker and communication equipment are present outside the confined space.

- I have thoroughly reviewed the emergency response measures.

- I have not consumed alcohol or unapproved drugs before entry.

- I will strictly follow the confined space work procedures.

Protect Yourself from Fall Hazards When Working at Heights

- I have correctly worn my personal protective equipment (i.e., a full-body harness).

- Staff have inspected my fall protection equipment and confirmed it is in good condition.

- I have not consumed alcohol or unapproved drugs.

- I will strictly follow the work-at-height procedures.

Properly Plan Lifting Operations and Manage the Work Area

- I will never stand or walk under a suspended load.

- I have confirmed that the area for lifting and moving suspended loads is properly barricaded and marked with warning signs.

Ensure You Have a Valid Work Permit When Required

- I have confirmed whether the work I am about to perform requires a permit.

- I am qualified to perform this work.

- I understand the content and form of the permit.

- I have confirmed that the risks have been controlled and that I can begin work safely.

- If an immediate danger arises during the work, I will stop working and evacuate immediately.

Keep Yourself and Others Away from Danger

- I will not wear loose clothing or accessories that could get caught.

- I will not cross any barriers or enter restricted areas.

- I will ensure my position is safe to avoid being struck by objects, flying debris, high-pressure gases, or rotating equipment and vehicles.

- I will take necessary precautions to prevent any objects from falling and hitting personnel or equipment.

Follow Safe Driving Rules

- I have obtained permission to drive the vehicle or machinery.

- I am qualified to drive the vehicle or machinery.

- I will make sure to wear my seatbelt.

- I will not speed.

- I have not consumed alcohol or unapproved drugs.

- I will not use my cell phone while driving.

- I will remain fully sober and alert while driving.

- When passing through intersections, I will watch for pedestrians and blind spots.

Safety Performance Indicators and Targets

TCC continues to advance various occupational safety management initiatives to prevent injuries and accidents during all personnel and production activities. The company regularly updates and publishes its safety performance indicators, which serve as a benchmark for the continuous improvement of its occupational health and safety management.

Targets of Taiwan and Mainland China

Total Recordable Incident Rate (TRIR)

35%

2016-2018 Average Baseline

(including contractors)

Lost Time Injury Frequency Rate (LTIFR)

35%

2016-2018 Average Baseline

(including contractors)

Targets of CIMPOR & OYAK CEMENT

By 2030

Lost Time Injury Frequency Rate (LTIFR)

reduced to below

1

By 2030

Lost Time Severity Rate (LTISR)

reduced to below

0.001

2021 | 2022 | 2023 | 2024 | ||

|---|---|---|---|---|---|

Employees | Number of Fatalities | 0 | 0 | 0 | 0 |

| Lost Time Injury Frequency Rate (LTIFR) | 0.55 | 1.00 | 0.80 | 1.94 | |

| Total Recordable Injury Frequency Rate (TRIFR) | 0.55 | 1.00 | 0.80 | 1.94 | |

Contractors | Number of Fatalities | 1 | 0 | 2 | 4 |

| Lost Time Injury Frequency Rate (LTIFR) | 0.00 | 0.75 | 0.60 | 3.25 | |

| Total Recordable Injury Frequency Rate (TRIFR) | 0.35 | 0.75 | 1.15 | 3.66 | |

Note

- Lost Time Injury Frequency Rate (LTIFR) = (Number of Recordable Work-related Injuries - Number of Fatalities / Total Actual Working Hours) x 1,000,000.

- Total Recordable Injury Frequency Rate (TRIFR) = (Number of Recordable Work-related Injuries / Total Actual Working Hours) x 1,000,000.

- Newly added in 2024: Huaihua, and Liaoning cement plants; Fuzhou and Liuzhou grinding plants; 123 Environmental Protection Technology Co., Ltd., Beijing TCC Environmental Technology Co., Ltd., TCC (Guangdong) Renewable Resources

Technology Company Limited, Feng Sheng Enterprise Company, E.G.C. Cement Corp., Ho Sheng Mining Co., Ltd,Wanching Mining Co., Ltd, , TCC Jiuyuan (Guangan) Environmental Technology Co., Ltd.,Hangzhou Operations Center, Guangdong–Guangxi

Operations Center, TCC Yingde Mining Industrial Company Limited, TCC Guigang Mining Industrial Company Limited, TCC Jiangsu Mining Industrial Company Limited , Hong Kong Cement. - In 2024, CIMPOR & OYAK's Work-related Injuries of Employees is 3.58, recordablework-related injuries rate is 3.58; work-related injuries rate of contractors is 4.09,and recordable work-related injuries rate is 4.09

Comprehensive Health and Wellness Care

To fulfill our corporate social responsibility of caring for employees, the company not only actively promotes regular exercise habits but also arranges annual health check-ups and provides employees with a range of other measures, including:

Health Services: General health services with 100% employee coverage

Employee Assistance Program (EAP): Offering an annual one-on-one consultation, toll-free Employee Care Hotline, regular stress relief seminar

Nursing Room: Facilities are available at all operational locations, with unlimited access during lactation, with time counted as regular working hours

On-site Health Services: A contracted doctor and an occupational safety and health nurse are arranged quarterly to provide on-site health consultations for employees

Diverse Communication Channels

Transparent and unobstructed communication channels in the work environment, the company allows employees to report issues and receive assistance in a timely manner.

Occupational Disaster and Major Incident Reporting System and Mobile App (under development)

Grievance Mechanism: for suspected occupational illnesses, or physical or mental harm

Contct Us

Emergency Response / Direct Mitigation Measure

A fire at Molie Quantum Energy Corporation (Xiaogang plant) on July 14, 05:04, began in a non-operational area; firefighters arrived 05:21. The Li-ion fire reignited overnight, extinguished 08:00 next day; environment conditions normal. 15 minor injuries, most were minor; 2 hospitalized released in 4 days. MoE's 3-day monitoring traced hydrofluoric acid detected at the fire scene on July 14 09:47, believed to be from residual electrolyte, did not spread to surrounding areas. A July 16 Kaohsiung Gov't release confirmed no toxic gas; EPA's 3x-daily tests thru July 24 were normal. Immediate evacuation response flaws (e.g., flash explosions, assembly point) will be fixed. Fire did not affect UHPC storage cabinets (tested <100°C surface after 2hr at 1000°C, a safety level far superior to standard metal cabinets), now powered down. TCC Chairman formed a task force for strict accountability under company rules. Post-investigation, plant restructure and management review are priorities.

Prevention Measures

Processes/mechanisms were strengthened: The Xiaogang plant cooperates with fire/police investigations; however, controlled site access prevents retrieving the core-zone mainframe, delaying assessment of links to operational processes. Suppliers are analyzing sensor and multi-stage suppression system malfunctions. Planned enhancements include: improving machine suppression via AI-assisted early intervention and more testing; fortifying the non-conforming product process with error-proofing and integrity safeguards; and using fire/explosion-proof structures in reconstruction while evaluating remote/robotic firefighting to reduce human risk. Concurrently, at sister facility E One Moli Corporation (Tainan plant), Li-ion production fire safety is being optimized; its EHS department has increased inspections, inventoried high-risk equipment, and advanced emergency drills for completion by August 31. To build public trust, third-party experts are engaged to review the full optimization process at both Xiaogang and Tainan plants.

Policies were strengthened: The Xiaogang plant will optimize emergency response procedures by relocating assembly points to increase the safety distance from the facility, thereby enhancing personnel evacuation safety. Operational protocols will be further strengthened in accordance with the existing ISO 45001 certification. This includes adding hardware infrastructure within various process areas to serve as effective firebreaks and prevent disaster escalation. Furthermore, the Environmental, Health, and Safety (EHS) policy will be revised to include new requirements such as "Hazardous Chemical Labeling" to ensure informational transparency and alleviate concerns within the surrounding community.

Training was provided: Xiaogang plant will continuously review and enhance the battery plant's safety standards and emergency response mechanisms. Internal firefighting capabilities will be improved by establishing an in-house team, providing professional training to current staff, and hiring firefighting professionals to strengthen the response to new types of fire incidents. A firefighting fund will also be established to assist neighboring fire departments acquire modern equipment, while enhanced cooperation will focus on jointly developing and drilling Standard Operating Procedures for lithium-ion battery fire response. Concurrently, the Tainan plant has scheduled internal emergency drills for 2025Q3 covering gas leak and electrical fire scenarios. Its Emergency Response Team will complete additional skills training before September to ensure rapid disaster control and the effective prevention of casualties.

The business unit/activity facing the issue was discontinued or reduced: In compliance with government regulations, Molie Quantum Energy Corporation (Xiaogang plant) will suspend operations for three months to facilitate the official investigation into the cause of the fire and subsequent damage assessment.

Remediation Measures

Per regulations, firefighting water was contained on-site (3,700 m³ reservoir) and trucked for off-site treatment to prevent high-pH discharge; daily truckloads were cut from 25 to 15 by July 24 using gravity-pumping to avoid motor noise. Unaffected air quality remains under gov't monitoring. Employees receive full pay. A third-party Employee Assistance Program (EAP) offers free, confidential counseling (toll-free, 4 languages incl. Mandarin/English, 3 formats). Interest-free loans up to NT$600,000 aid staff in hardship, and town hall meetings provide updates. On community relations, a senior executive first phoning apologies to 38 community leaders (borough chiefs). The plant GM and managers then personally visited 13 community leaders and 8 households to gather feedback. Responsive initiatives include: transparent environmental reporting channel for emergency alerts, a stakeholder liaison, and future community health seminars to support the well-being of community elders.

Environmentally, fire water, settled in on-site grit chambers, was trucked to Linhai Industrial Park for disposal. All water passed pH/temp tests & met MoE discharge standards, causing no irreversible harm. Monthly public air monitoring (CO, HF, PM, TVOCs) will run for 4 months; all data is compliant. EAP effectiveness will be gauged by participation & feedback. Safety training/drills face rolling reviews; surveys will assess compensation. Parent TCC's CSDDD (human rights/environment) will extend to local residents. A local hiring target will be set with chief's input, using the 18.6% local hire rate as a baseline. A dedicated team is surveying local opinion via visits/calls. Regarding business partners, close communication is maintained with supportive customers and suppliers. Supply chain partners understand the recovery timeline and are cooperating to ensure the stable supply of key materials and components. While basic customer needs will be met, maximum volume is not possible.

Related Information

Report: Molie Quantum Energy Xiaogang Plant Fire Incident Progress Report (July 14 - July 27)

Press Release: Forged Through Setbacks, Keep Moving Forward for Taiwan's Battery Cell Technology

Press Release: TCC Estimates 11 Billion NTD Loss From Kaohsiung MQE Battery Plant Fire; Human Operation or Mechanical Defects Suspected